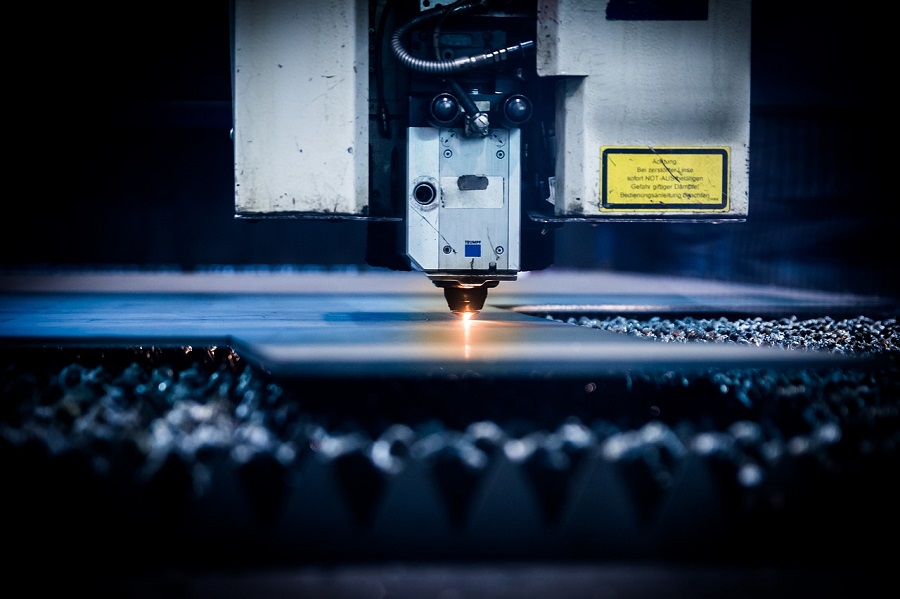

While most people may not realise it, laser cutting machines are becoming more and more common in the world of business. Indeed, there are many business applications of laser machines, including but not limited to, school uses and small businesses. Laser cutting technology has been a staple of industrial manufacturing sector for some time, primarily because of its accuracy and energy efficiency.

If you’re in need of assistance when it comes to laser machines and laser cutting (let’s face it, most of us probably do), then make sure you get in touch with a well-respected retailer, like Koenig Machinery. Thankfully, Koenig have an extensive catalogue of various laser cutting machine models, including both CO2 and Fiber laser models.

CO2 models

CO2 laser machines are incredibly safe and easy to use. They are strong enough to cut through various materials, including plastic, leather, wood and some types of metal. A laser beam is a high intensity column of light. Typically, a conventional CO2 model will use the infrared part of the light spectrum, so it is visible to the human eye. Generally, the beam is approximately ¾ of an inch.

Fiber laser models

Essentially, a fiber laser machine is more energy efficient and stronger than a traditional CO2 model. Put simply, a CO2 model can only cut through some types of metal, whereas a fiber model is much stronger, cutting through copper, aluminium and brass. On average, your typical fiber model boasts operating costs that are less than half of a CO2’s operating cost. Fiber laser beams also provide much faster cutting speeds when compared to your regular CO2 version, meaning you will be able to churn through more work at a much faster rate.

Moreover, fiber laser beams don’t require any warm-up time. Typically, a CO2 laser cutting machine needs approximately 10-15 minutes of warm up time before it can be utilised. Fiber laser machines are also much safer when in operation.

Which machine is right for you?

If you’re in need of a laser cutting machine, the choice is obviously up to you. Consider your business operations before making any decision – is it a high intensity industry, characterised by high volume and productivity? If so, a fiber laser model might be worth investing in given the amount of time saved per project, the energy efficiency, the higher quality output and the safety of use.

On the other hand, if you’re working in a field that is less intensive and costs are not a massive consideration, then perhaps a cheaper CO2 model is a better bet. If you need several machines, a mixture of both fiber and CO2 models could be your best option, as you’re covering all bases when it comes to your productivity needs.