Have you been debating the pros and cons of an automatic strapping machine? If you use strapping tools in your industry, your options range from manual tools to semi-automatic, and finally to fully automatic machines.

Firstly, what’s a “strapping” machine? Strapping, also known as banding or bundling, is a form of packaging which is used to fasten products in many industries.

The materials used for strapping range from steel, which is used in construction and heavy manufacturing, to various plastics: these are used in many different industries. Paper strapping is also used in industries that need lightweight applications to prevent damage to products.

Which type of strapping machine you choose for your products will depend not only on the products you need to strap, but also on how the products are intended to be handled, stored, and shipped.

If you’ve decided that you need a high-volume strapping solution for your warehouse or factory, you have a choice: semi or fully automatic?

While manual tools are adequate for small volumes of products in many industries, heavier and larger volumes in manufacturing or construction industries require automation. The automated machines improve the strapping, sealing, and bundling processes in your storage, warehouse, or factory. These machines are available as semi-automatic machines, as well as fully automatic.

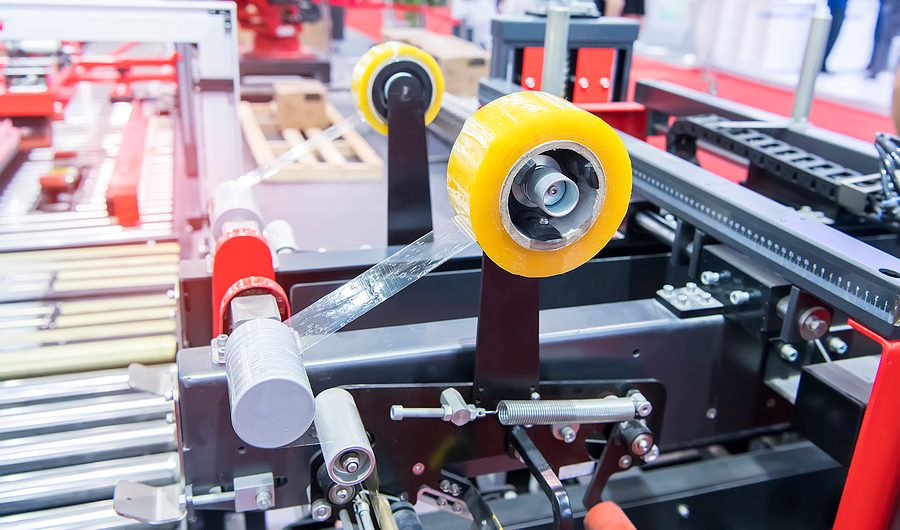

The fully automatic strapping machines are simple to operate, and designed in such a way that they can operate at high speed. These machines are integrated with the reversible cutter, and enhanced cam profile and used for applications like corrugated bundling, and can successfully handle the corrosive wet conditions of food and meat processing industries.

A fully automatic strapping machine: the pros

After an operator sets the required tension on a fully automatic strapping machine, it operates at the touch of a button. The machine applies the correct tension every time, to each package.

Let’s look at the pros of an automatic strapping machine; they’re considerable.

1. Speed: a fully automatic machine increases productivity

An automatic strapping machine improves productivity. It’s high-volume and typically operates at 60 straps per minute on a production line.

With the machine set up on your factory floor, you’ll save time. Products can be strapped more quickly, as well as more consistently. Workers can quickly adjust the tension in an automatic machine; packages are therefore wrapped at precise tensions each time.

This leads to increased productivity with less damage to products, as well as time savings.

2. Cost savings: automation means fewer damages, as well as savings in the costs of materials

An automatic strapping machine is consistent. No matter how heavy or awkward a bundle of products may be, the machine applies the right tension to the strap. This leads to fewer breakages and less damage to items while on the factory floor, and in storage and shipping.

The machine also offers savings in the costs of strapping materials—generally less strap is required. It will cut the strap precisely to the tension required with less waste.

3. Improved operator safety: an automatic strapping machine can mean fewer injuries

Injuries occur when operators are dealing with heavy and awkwardly-shaped products, especially when using steel banding. Automatic machines can help to reduce the number of injuries, especially those caused by operator fatigue.

4. A quick return on investment: automatic strapping machines are durable

Every business is concerned with costs and lowering costs. Does an automatic strapping machine offer a good return on investment?

Automatic machines are durable. This means that the machine will quickly pay for itself when its cost is amortized over several years.

5. Safety of the workers

Workers don’t need to work in working conditions like being exposed to heat or metal. Hence, these machines ensure the safety of the employees/workers.

A fully automatic strapping machine: the cons

Fully automatic strapping machines are available in various product and batch sizes and are designed to meet all of the expectations of today’s packaging industry. These machines are indispensable when it comes to the safety of goods for transport. While there are many benefits to an automatic strapping machine, there are also challenges. Let’s look at some of the cons.

The biggest con will be the cost, closely followed by the costs of training staff to use the machine and inevitable costs of downtime for repairs.

1. The biggest con: the cost—an automatic strapping machine is expensive

Compared to manual tools and semi-automatic machines, fully automatic machines are a big investment.

Consider getting advice for your situation. Look at different brands available.

Make a list of your requirements, then look at what each brand offers:

- What safety features does a machine have?

- Does it have self-diagnostics?

- How often does the machine require servicing?

Although the machine is expensive, you may discover that it repays its cost quickly in improved productivity.

2. Training costs for your operators

When your automatic strapping machine is installed in your warehouse or factory, you’ll need to train your staff in operating the machine, as well as in health and safety issues.

Before deciding on a machine, check with the seller on training: does the company offer training for its customers, and how much training is offered? Is the training offered on-site?

3. Costs of downtime for maintenance and repairs

All machines require maintenance. Check the manual which came with your machine for guidance on regular servicing if you intend that your staff will maintain the machine. Alternatively, ask the machine’s seller for a maintenance agreement.

Check the machine’s manual for a list of parts, and part numbers, so you can order parts when required.

An automatic strapping machine: an investment in productivity

Once installed, your automatic strapping machine will boost your operation’s productivity. The machine can make a huge difference in your company’s profitability.