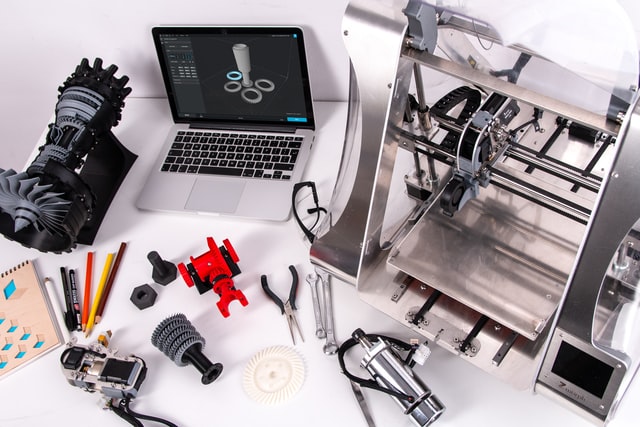

Despite not being the world’s fastest adopter of 3D printing technology, Australia has been quick to jump on the additive manufacturing bandwagon, and demand for skilled and industrial-grade 3D printing solutions is expected to grow over the next five years. The 3D printing industry in Australia was projected to be worth $70 million in 2021.

The technology is evolving from being used by hobbyists to industrial and commercial applications, echoing global trends on a smaller scale. This article will explain how 3D printing is being used in Australia across industries, recent breakthroughs in the field, and future additive manufacturing trends to expect in 2022 and beyond.

A brief glance at the rapidly expanding 3D printing market in Australia

After taking a knock when the pandemic began, demand for 3D printing in Australia has returned to full throttle. The primary factors are technological efficiency, reduced manpower, and minimal resource waste. It was a relatively new concept until 2017. But now, many companies have started using 3D printing services in Australia to make more than half of their goods since last year.

In the year 2022, the figures are likely to rise even more. The technology is presently being employed in a variety of sectors ranging from education, healthcare, construction to food, housing industry, among others.

Application of 3D printing in various sectors in Australia

Australia’s manufacturing sector contributes 6% of the country’s GDP. Production revenue from food and beverages accounts for 30% of overall manufacturing earnings. The major subsectors are meat and meat products, drinks, and dairy goods. Printing, paper and pulp, metals and machinery, chemicals, and equipment are among the other major manufacturing industries.

Food and drinks, along with defence and aerospace, medical, and space, are four of the six national priority sectors that the Australian government is prioritizing. These industries already have scope for the 3D printing market. Architecture, dentistry, and automotive are the other niches that hold promise for additive manufacturing.

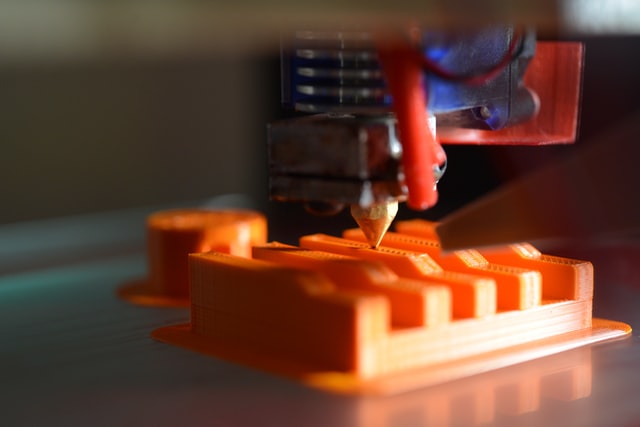

Concept modeling and prototyping are the two most common uses of 3D printing in Australia. Manufacturing of production parts is another application. However, the in-house application of 3D technology is still not a common concept in this part of the world. 3D printing is still mostly outsourced for commercial and industrial purposes.

Machine tool distributors are gradually introducing additive manufacturing processes to their product lines. The existing distributors primarily focus on 3D printing solutions and peripherals. Here’s a look at some of the industries in Australia where 3D printing is already making a difference.

Healthcare

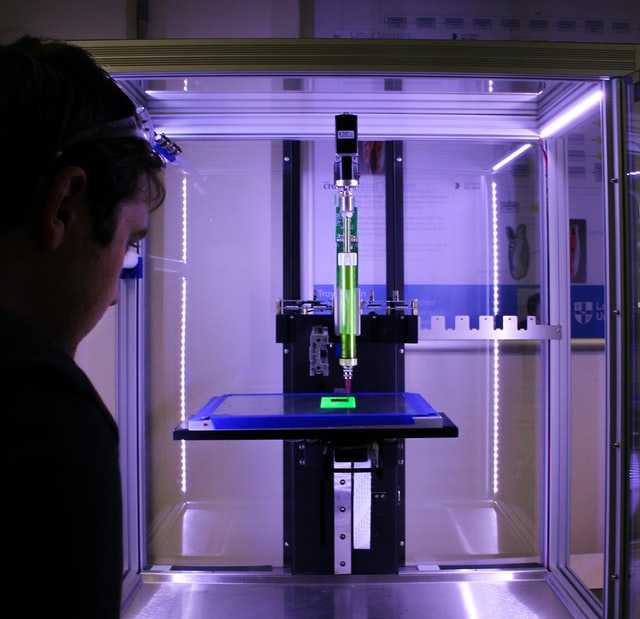

By adopting 3D printing in healthcare, Australian medical professionals can provide patients with a range of cutting-edge treatments. This includes prosthetics, surgical guides, and customized replicas of organs, blood vessels, and bones for surgical planning, so that surgery time is reduced, and patient outcomes are improved.

Advances in 3D printing have led to lighter, safer, and sturdier products; shorter lead times; and lower costs in healthcare. Medical professionals can better understand patients by creating custom parts for different individuals. Patient comfort levels will be improved by interacting with products that are specifically designed for their anatomy.

Housing

What are the chances that 3D house-printing will help regional Australia’s housing crisis? As homes become increasingly scarce and expensive in regional Australia, smaller cities are considering investing in a pilot program to make 3D-printed houses locally, hoping it will prove to be a game-changer.

Who would have imagined that 3D printers would be able to build houses? The first 3D-printed house in Australia was built in just three days. With the potential for houses to be constructed quickly, more cost-effectively, and in an environmentally friendly manner, Australia’s authorities are now evaluating whether the technology can help alleviate the country’s worker and material shortages.

Education

Australia’s education sector has reaped the benefits of 3D printing by making education more accessible to visually impaired students. The materials include tactile globes and brain components and are “leading examples of inclusive education models.”

The materials are widely loved by students and enhance their engagement with learning, not only by those who have poor vision or are blind.

Defence and aerospace

Australia’s defence and aerospace engineers are always looking for ways to create products that are more durable, ingenious, and lighter. 3D printing makes it possible to design and test prototypes rapidly, reducing development time and saving significant amounts of money for engineers creating futuristic drones, airplanes, spacecraft, and more.

In addition to producing materials such as aircraft wings, additive manufacturing can replicate engine components and parts. Furthermore, it can also be used to create items that support the manufacturing process, such as brackets and mounts. Making functional end-use parts is also a realistic goal, especially with modern 3D printers that can print out composite and metal materials.

Food industry

Do you know that the Australian Meat Processor Corporation developed the first industry-owned 3D printing service model in the world that enables red meat processors across Australia to replace 3D printed parts, reforming the process of equipment maintenance?

Because red meat is one of Australia’s prime exports, this three-year effort will ensure that the high-volume orders are met in meat processing factories around the country. Another example demonstrating developments in the field includes researchers from Australia’s Deakin University and the University of Technology Sydney using AM technology to develop meals for individuals with swallowing difficulties (dysphagia) that are both tasty and safe to eat.

Future trends

The manufacturing sector causes significant environmental damage. 3D printing has the potential to reduce global warming and environmental problems. 3D printing is significantly more efficient than most other manufacturing methods since it produces very little waste. The raw ingredients and inks are largely made from recycled resources by 3D printing services in Melbourne. This could provide solutions to the world’s current environmental concerns. This isn’t merely a musing.

Many big manufacturers are switching to 3D printing or are exploring the pros and cons of how it may be used. The railway sector already finds additive manufacturing to be a beneficial tool. Spare parts have traditionally had a long lead time in the railway industry. Obtaining the required spare parts can take months. Tasks can be completed in as little as a few weeks with 3D printing. In general, additive manufacturing appears to have a promising future in Australia.

The way forward

3D printing offers a mechanism to respond to changing constraints such as supply chain complexity, growing labour costs, and the misery of distance, all of which are relevant to the Australian setting. Adoption, on the other hand, will take time and work to accomplish. Critical issues like branding, regulatory, and environmental issues must be handled and controlled.

The challenges of distribution and production will persist, and the government needs to address them. While professional 3D printing businesses print the most durable objects, devices are hard to distribute uniformly throughout Australia because of the large scale of the country. A business may want to outsource the requirements in that case.